Peening and Problems

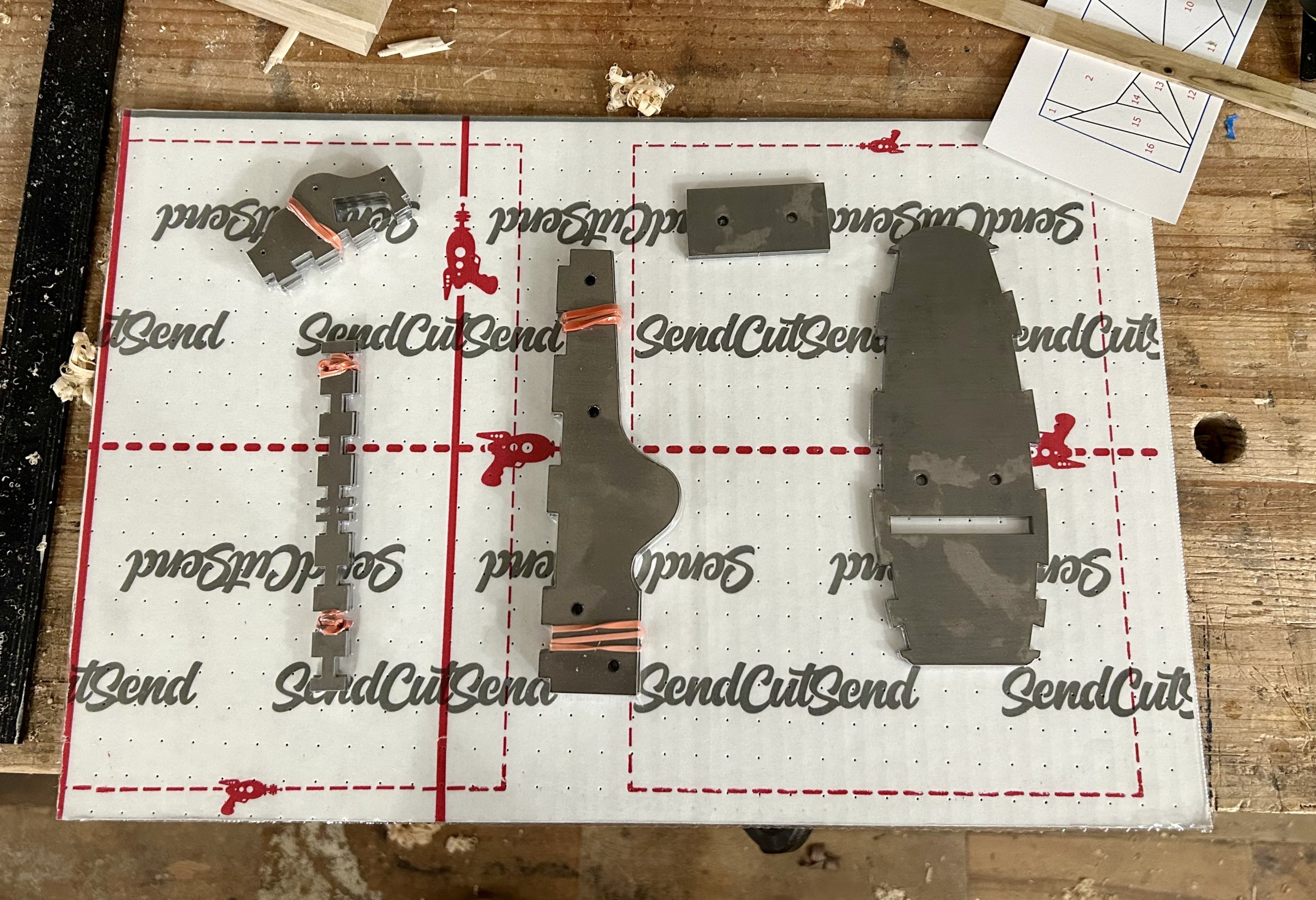

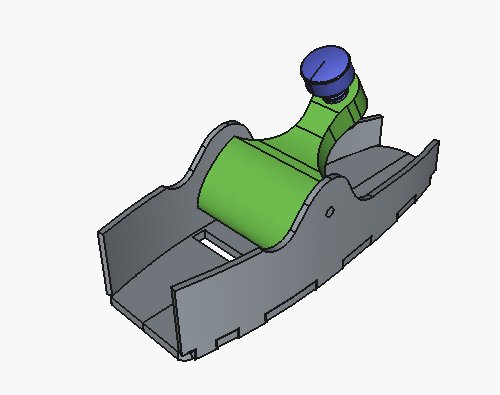

Having now fully peened the shell I am realizing some challenges of the design choice I made for how to structure the dovetails. The traditional "double dovetail" is what I've seen on most modern makers' planes as well as read about. However, examining the antique example, the tails coming off of the sides were visually straight. So I replicated that in this plane. The end result, likely due to my inexperience, was that the peening process lifted the toe end of the sides off of the sole as the metal pushed it up. If I'd been able to peen the ends of the tails on the sides first, it would have locked it in place and prevented that from happening, but a combination of the design and not leaving enough meat on those parts prevented doing that. I will redesign the side for future planes. Fortunately, the sides are structurally locked in; reasonably application of force doesn't result in any movement. So I will fill the gaps with some Devcon 10110 and move on.