Final photography

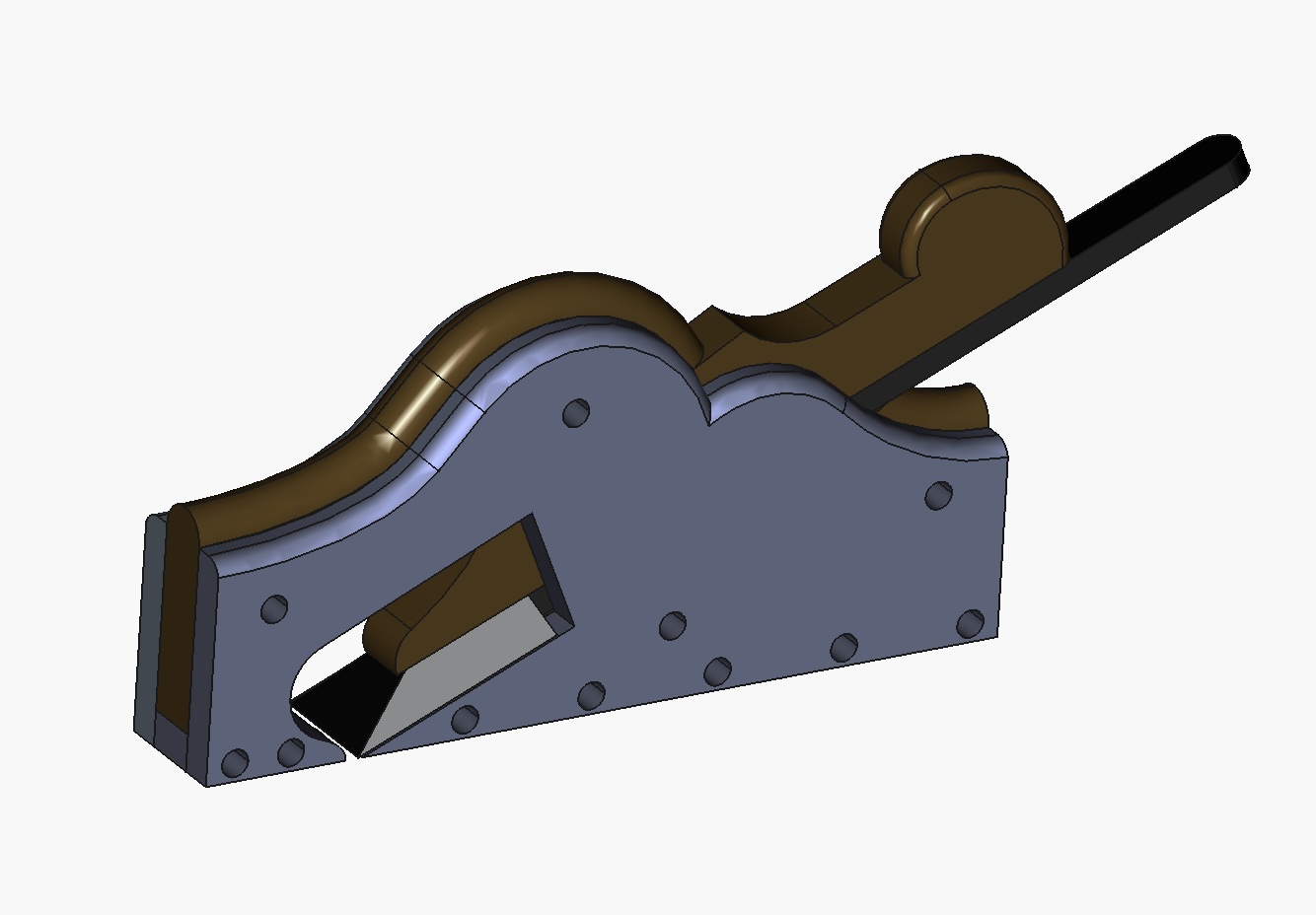

Now I have to give some thought to how I'm going to open the mouth.

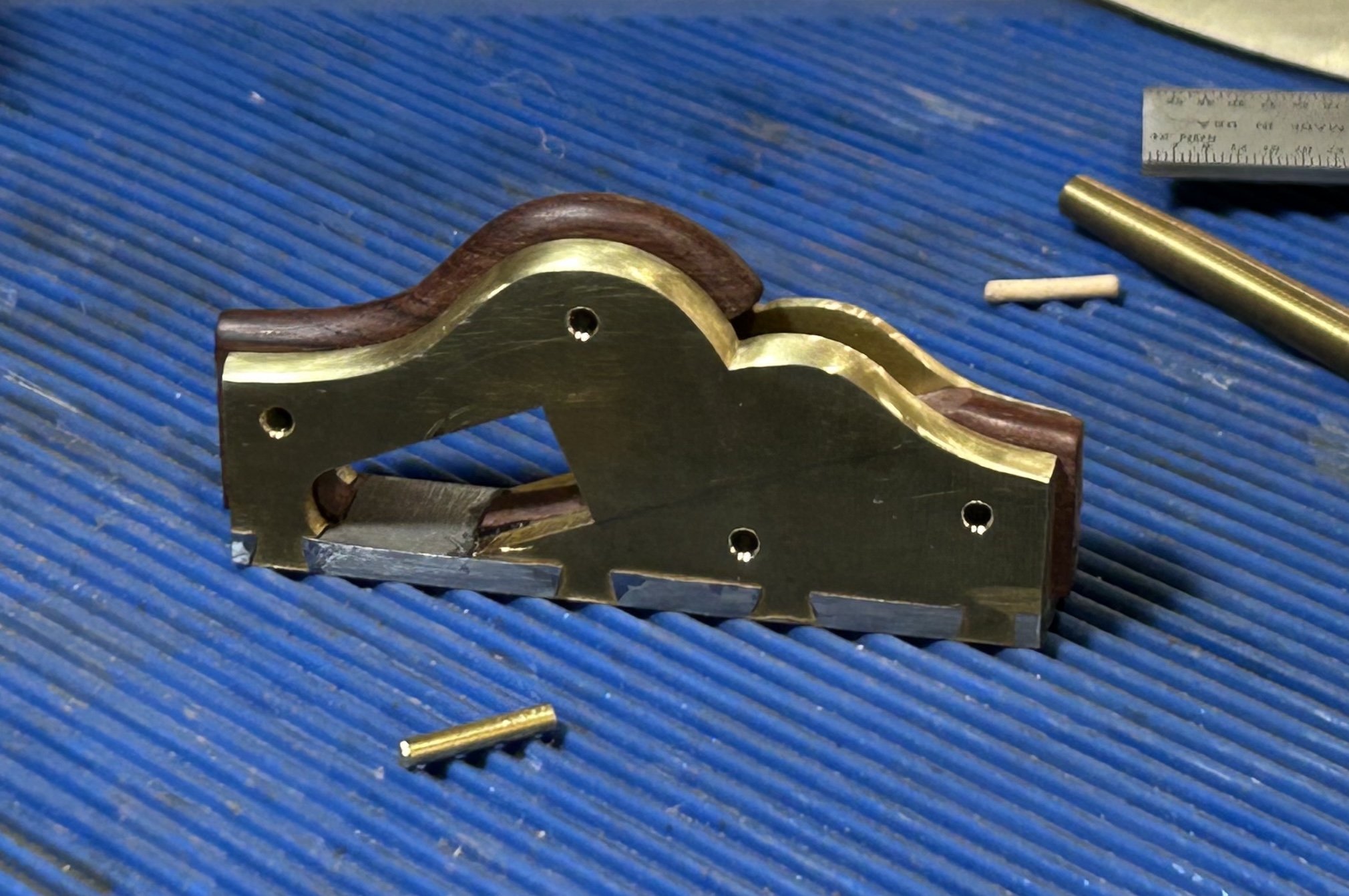

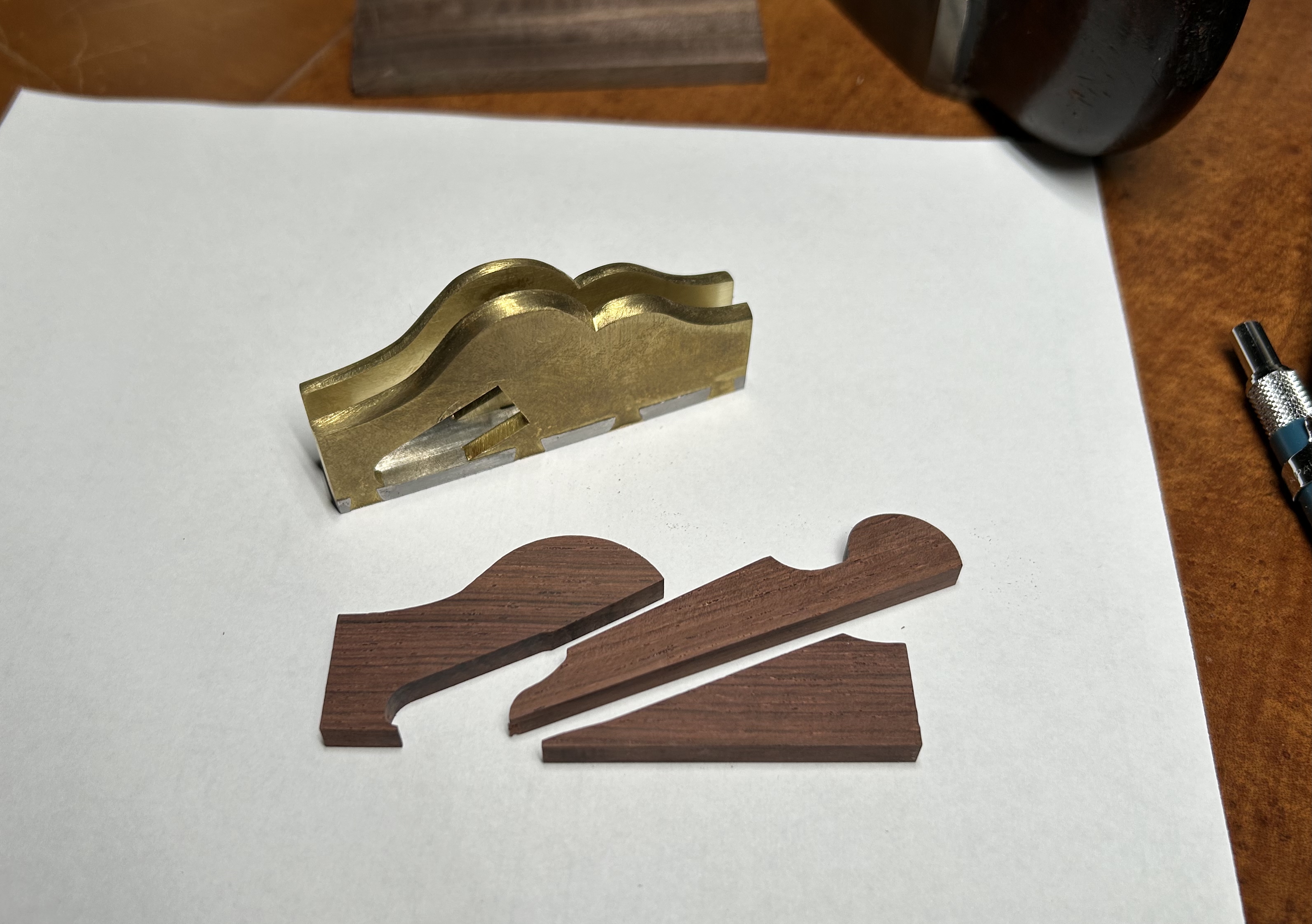

Looking at this side-by-side with the original either my pattern on the rear infill was off by a bit or, more likely, I filed it too aggressively. I'm going to re-cut it with a bit more meat peeking up over the side of the brass and see if I can get it looking less flat at the back. I intentionally left a bit extra sticking out the front and back so that it could be sanded flush after it is attached. The sharpest points of the wood were also left chunky to protect them. They'll get filed back as well once everything is in its final place.

The rosewood took a wonderful burnish; it's exciting to see it coming together at this point.

Then it was on to adding edge profiles to the top and ends of the brass. The convex parts were rough shaped with a flat file and then faired with 120 grit sandpaper. It will get a higher degree of polish later in the process, but this is all I need now for the shaping.

I cut the sole in my shop from 0.5\" x 0.125\" bar stock. My machining set-up is rudimentary. I've got a vintage Unimat (DB-200) that is both tiny, and has the rigitity of a wet noodle when milling, so most of the work here is hack saw and file. It should be good enough for drilling my pin holes when I get there.

As for the dovetails, these were surprisingly similar to cutting them in wood, just replace the chisel with a safe-edge file, and the dovetail saw with a hack saw and it's more or less the same.

The brass version will have a dovetailed base, the other two will be pinned.